Determining which cut resistant gloves level 5 to trust for the utmost hand protection can be daunting. This article helps you navigate through the key elements—material strength, compliance with safety standards, and real-world applications—to make an informed choice. Find out which gloves are cut above the rest, offering the protection your hands deserve.

Key Takeaways

- Level 5 cut resistant gloves offer the highest degree of protection against cuts, tears, punctures, and abrasions, using materials such as HPPE and steel fibers to create an almost impenetrable barrier.

- Proper glove selection must consider the task and environment, with Level 5 gloves mandatory in extreme cut-risk industries. Enhanced features like PU palm coating and touchscreen compatibility cater to specific work needs while maintaining protection.

Maintenance of Level 5 gloves is important for preserving their protective qualities, and innovations in glove technology are continuously improving their resistance, breathability, and dexterity.

Decoding Cut Resistant Glove Levels: Focus on Level 5

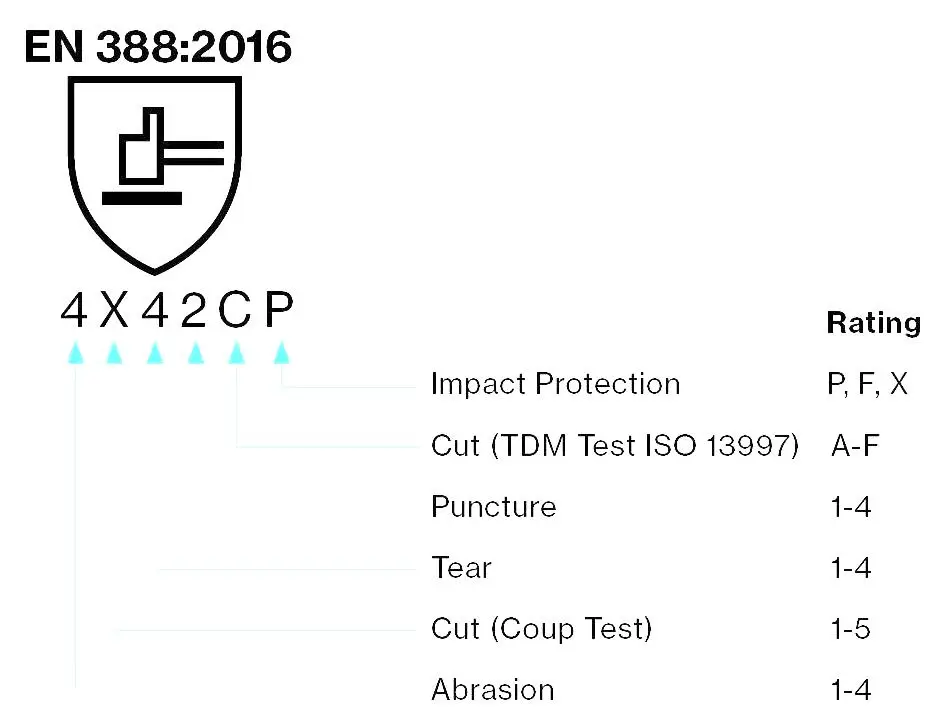

Recognizing the different levels of cut resistant gloves is crucial for ensuring hand safety. The ratings assigned to these gloves indicate their capacity to shield your hands from cuts and wounds effectively. At the top tier, Level 5 cut-resistant gloves offer unmatched protection in situations dominated by sharp objects.Consider these protective gloves as a component of your protective equipment arsenal—they are designed as safety gloves that provide a robust defense against harsh cutting actions and piercing edges that could lead to serious harm without proper protection.