Work gloves play a vital role in protecting workers from hazards in the workplace, and it’s important to ensure that they meet certain standards and regulations to ensure their effectiveness and safety. In Europe, there are several standards and regulations that apply to work gloves, including the European Personal Protective Equipment Directive (PPED) and the EN 420 standard. In this article, we’ll explore the key European work gloves standards.

https://europa.eu/youreurope/business/product-requirements/labels-markings/ce-marking/index_en.htm

The European Personal Protective Equipment Directive (PPED)

The European Personal Protective Equipment Directive (PPED) is the European work gloves standard that sets out the minimum safety and performance requirements for personal protective equipment (PPE). The PPED applies to all types of PPE, including safety gloves, and covers a wide range of issues, including design, construction, and performance level such as abrasion resistance, cut resistance, puncture resistance and tear resistance, labeling, and testing.

Under the PPED, all work gloves must meet certain basic health and safety gloves requirements, including:

Being safe to use

Being suitable for the intended use

Being properly marked and labeled

Being accompanied by instructions for use

In addition to these basic requirements, the PPED also sets out specific performance requirements and safety standards for different types of work gloves, based on the risks they are intended to protect against. For example, safety gloves that are intended to protect against cuts or punctures must meet certain minimum performance levels for resistance to cuts, abrasions, and punctures.

The EN 420 standard

The EN 420 standard is a European standard that sets out the general requirements for safety gloves, including design, construction, performance, and testing. The standard applies to all types of work gloves, including gloves made from leather, fabric, metal, or other materials.

According to EN 420 test methods standard, safety gloves must meet certain minimum requirements, including:

Being safe to use

Being suitable for the intended use

Being properly marked and labeled. The label should include the following information: Fiber composition Care instructions and symbols Size Non-textile parts of animal origin You must specify if the glove products you import to the EU contain leather and other parts of animal origin. Label file Creating a file for all the labeling documents and requirements for the related products can make your manufacturing process easier and avoid minor mistakes and labeling issues.

Being accompanied by instructions for use

In addition to these basic requirements, this standard also includes specific requirements for different types of safety gloves, based on their intended use. For example, gloves that are intended to protect against cuts or punctures must meet certain minimum performance levels for resistance to cuts, abrasions, and punctures.

Other standards and regulations for work gloves in Europe

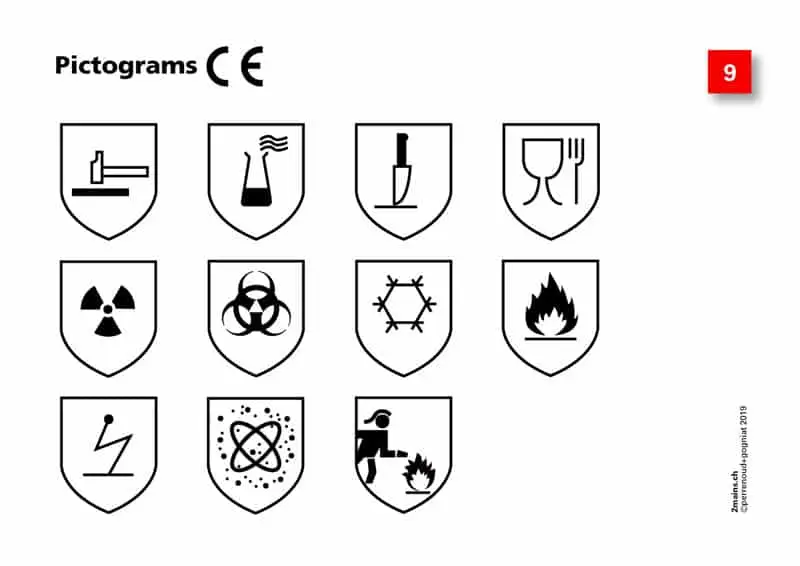

In addition to the PPED and the EN 420 standard, there are several other standards and regulations that apply to work gloves in Europe, depending on the specific hazards they are intended to protect against. Some examples of these standards include:

EN 388: Protective gloves against mechanical risks

what are EN 388 standards?

The EN 388 standard is a European standard that sets out the requirements for protective gloves against mechanical risks. The standard applies to all types of gloves that are designed to protect against mechanical risks, such as cuts, abrasions, punctures, and tears. It is commonly used to evaluate gloves that are used in industries such as construction, manufacturing, and agriculture, where there is a risk of hand injuries from sharp or abrasive objects.

1.Resistance to abrasion: This test measures the ability of the gloves to resist wear and tear from abrasive surfaces. The gloves are subjected to abrasive paper or fabric, and the number of cycles required to wear through the material is recorded. A higher number of cycles indicates a higher level of resistance to abrasion. Unlike the old standard, new abrasive paper will be used. For which, some abrasion scores may change when a product is re-certified under the new test conditions. The impact test is included in the list that claims specific impact-resistant properties. The marking will include a ‘P’ to indicate the glove has passed the impact test. The glove marking will now feature two additional components. Share this Term Related Terms Cut-Resistant Gloves Anti-Vibration Gloves Abrasion-Resistant Gloves Puncture-Resistant Gloves Work Gloves Related Reading Comparing EU Health & Safety Laws Across European Countries qualities.

2.Blade cut resistance: This test measures the ability of the gloves to resist cuts from sharp objects, such as knives or blades. The gloves are subjected to a blade with a specified force, and the depth of the cut is recorded. A deeper cut indicates a lower level of cut resistance.

3.Tear resistance: This test measures the ability of the gloves to resist tearing when subjected to a specified force. The gloves are subjected to a tearing force, and the amount of force required to tear the material is recorded. A higher amount of force indicates a higher level of tear resistance.

4.Puncture resistance: This test measures the ability of the gloves to resist punctures from sharp objects, such as needles or nails. The gloves are subjected to a puncture force, and the amount of force required to puncture the material is recorded. A higher amount of force indicates a higher level of puncture resistance.

5.Impact protection: This test measures the ability of the gloves to absorb and disperse impact energy. The gloves are subjected to a specified impact force, and the amount of force required to break through the material is recorded. A higher amount of force indicates a higher level of impact protection.

The results of these five tests are used to assign a numerical rating to the gloves, which is displayed on the gloves’ label. The rating consists of four numbers, with each number corresponding to the performance of the gloves in one of the five tests. For example, a rating of 4 2 4 4 would indicate that the gloves have a high level of resistance to abrasion (4), a moderate level of blade cut resistance (2), a high level of tear resistance (4), and a high level of puncture resistance (4).

By meeting the requirements of the EN 388 standard, work gloves can help protect workers from the mechanical risks present in their work environment and reduce the risk of hand injuries. It’s important for workers to choose gloves that meet the appropriate EN 388 standard for their specific needs, and for employers to ensure that their employees have access to the appropriate PPE to keep them safe on the job.

EN 407: Protective gloves against thermal risks

what are EN 407 standards

The EN 407 standard is a European standard that sets out the requirements for protective gloves against thermal risks. The standard applies to all types of gloves that are designed to protect against heat, cold, or fire, including gloves made from leather, fabric, or other materials. It is commonly used to evaluate gloves that are used in industries such as welding, foundries, and bakeries, where there is a risk of hand injuries from heat or cold.

The EN 407 standard consists of seven tests that evaluate the performance of gloves against different thermal risks. These tests are:

1.Resistance to flammability: This test measures the ability of the gloves to resist ignition and the spread of flame. The gloves are subjected to a flame, and the time it takes for the flame to ignite the material is recorded. A shorter ignition time indicates a lower level of resistance to flammability.

2.Contact heat resistance: This test measures the ability of the gloves to protect against contact heat. The gloves are subjected to a specified temperature, and the time it takes for the heat to be transmitted through the material is recorded. A shorter transmission time indicates a lower level of contact heat resistance.

3.Convective heat resistance: This test measures the ability of the gloves to protect against heat transfer by convection. The gloves are subjected to a stream of hot air, and the temperature of the material is recorded. A lower temperature indicates a higher level of convective heat resistance.

4.Radiant heat resistance: This test measures the ability of the gloves to protect against heat transfer by radiation. The gloves are subjected to a radiant heat source, and the temperature of the material is recorded. A lower temperature indicates a higher level of radiant heat resistance.

5.Small splashes of molten metal: This test measures the ability of the gloves to protect against small splashes of molten metal. The gloves are subjected to a specified number of splashes of molten metal, and the number of splashes required to break through the material is recorded. A higher number of splashes indicates a higher level of protection against small splashes of molten metal.

6.Large splashes of molten metal: This test measures the ability of the gloves to protect against large splashes of molten metal. The gloves are subjected to a specified number of splashes of molten metal, and the number of splashes required to break through the material is recorded. A higher number of splashes indicates a higher level of protection against large splashes of molten metal.

The results of these seven tests are used to assign a numerical rating to the gloves, which is displayed on the gloves’ label. The rating consists of seven numbers, with each number corresponding to the performance of the gloves in one of the seven tests. For example, a rating of 2 1 4 4 X 4 4 would indicate that the gloves have a moderate level of resistance to flammability (2), a low level of contact heat resistance (1), a high level of convective heat resistance (4), a high level of radiant heat resistance (4), no rating for small splashes of molten metal (X), a high level of protection against large splashes of molten metal (4), and a high level of cold resistance (4).

By meeting the requirements of the EN 407 standard, work gloves can help protect workers from the thermal risks present in their work environment and reduce the risk of hand injuries. It’s important for workers to choose gloves that meet

EN 374: Protective gloves against chemicals and micro-organisms

What are EN374 standards?

The EN 374 standard is a European standard that sets out the requirements for protective gloves against chemicals and microorganisms. The standard applies to all types of gloves that are designed to protect against chemicals, including gloves made from leather, fabric, or other materials. It is commonly used to evaluate gloves that are used in industries such as chemical manufacturing, cleaning, and healthcare, where there is a risk of hand injuries from exposure to chemicals or microorganisms.To protect from radioactive contamination, the glove has to be liquid-proof and needs to pass the penetration test defined in EN 374.

The EN 374 standard consists of four tests that evaluate the performance of gloves against different chemical and microbial risks. These tests are:

1.Penetration resistance: This test measures the ability of the gloves to resist the penetration of chemicals or microorganisms through the material. The gloves are subjected to a specified chemical or micro-organism, and the amount of time it takes for the chemical or micro-organism to penetrate the material is recorded. A shorter penetration time indicates a lower level of resistance.

2.Degradation resistance: This test measures the ability of the gloves to resist the degradation of the material due to exposure to chemicals or microorganisms. The gloves are subjected to a specified chemical or micro-organism, and the amount of time it takes for the material to degrade is recorded. A shorter degradation time indicates a lower level of resistance.

3.Permeation resistance: This test measures the ability of the gloves to resist the permeation of chemicals or microorganisms through the material. The gloves are subjected to a specified chemical or micro-organism, and the amount of time it takes for the chemical or micro-organism to permeate the material is recorded. A shorter permeation time indicates a lower level of resistance.

4.Breakthrough time: This test measures the ability of the gloves to resist the breakthrough of chemicals or microorganisms through the material. The gloves are subjected to a specified chemical or micro-organism, and the amount of time it takes for the chemical or micro-organism to break through the material is recorded. A shorter breakthrough time indicates a lower level of resistance.

The results of these four tests are used to assign a numerical rating to the gloves, which is displayed on the gloves’ label. The rating consists of four letters, with each letter corresponding to the performance of the gloves in one of the four tests. For example, a rating of S P A R would indicate that the gloves have a short penetration resistance (S), a low permeation resistance (P), a low degradation resistance (A), and a short breakthrough time (R).

By meeting the requirements of the EN 374 standard, work gloves can help protect workers from the chemical and microbial risks present in their work environment and reduce the risk of hand injuries. It’s important for workers to choose gloves that meet the appropriate EN 374 standard for their specific needs, and for employers to ensure that their employees have access to the appropriate PPE to keep them safe on the job.

EN 511: Protective gloves against cold

What are EN511 standards?

The EN 511 standard is a European standard that sets out the requirements for protective gloves against cold. The standard applies to all types of gloves that are designed to protect against cold, including gloves made from leather, fabric, or other materials. It is commonly used to evaluate gloves that are used in industries such as construction, transportation, and outdoor work, where there is a risk of hand injuries from exposure to cold temperatures.

The EN 511 standard consists of four tests that evaluate the performance of safety gloves against cold risks. These tests are:

1.Convective cold resistance: This test measures the ability of the gloves to protect against heat transfer by convection in cold temperatures. The gloves are subjected to a stream of cold air, and the temperature of the material is recorded. A higher temperature indicates a higher level of convective cold resistance.

2.Contact cold resistance: This test measures the ability of the gloves to protect against contact with cold surfaces. The gloves are placed on a cold surface, and the temperature of the material is recorded. A higher temperature indicates a higher level of contact cold resistance.

3.Water vapor resistance: This test measures the ability of the gloves to protect against water vapor. The gloves are subjected to a stream of water vapor, and the amount of water vapor that is transmitted through the material is recorded. A lower amount of transmitted water vapor indicates a higher level of water vapor resistance.

4.Water resistance: This test measures the ability of the gloves to protect against water. The gloves are submerged in water, and the amount of water that is transmitted through the material is recorded. A lower amount of transmitted water indicates a higher level of water resistance.

The results of these four tests are used to assign a numerical rating to the gloves, which is displayed on the gloves’ label. The rating consists of four numbers, with each number corresponding to the performance of the gloves in one of the four tests. For example, a rating of 3 2 1 2 would indicate that the gloves have a moderate level of convective cold resistance (3), a moderate level of contact cold resistance (2), a low level of water vapor resistance (1), and a moderate level of water resistance (2).

By meeting the requirements of the EN 511 standard, work gloves can help protect workers from the cold risks present in their work environment and reduce the risk of hand injuries. It’s important for workers to choose gloves that meet the appropriate EN 511 standard for their specific needs, and for employers to ensure that their employees have access to the appropriate PPE to keep them safe on the job.

By meeting these standards and regulations, work gloves can help ensure the safety and health of workers in Europe and protect them from the hazards present in their work environment. It’s important for workers to choose work gloves that meet the appropriate standards and regulations for their specific needs, and for employers to ensure that their employees have access to the appropriate PPE to keep them safe on the job.

WHO WE ARE?

Qingdao Pit Bull Safety Technology Co., Ltd.(PTB SAFETY) www.ptbsafety.com is a professional manufacturer of work gloves with over 15 years of experience in the industry. We produce a wide range of dipped work gloves, including cut resistant gloves,latex coated work gloves, nitrile coated gloves, and PU coated gloves. Our factory covers an area of 100,000 square meters and has 1,000 sets of various glove knitting machines and 17 dipping lines.

Our products are ISO9001, CE, ANSI, REACH and CAE certified.

You can be sure that our cut resistant gloves are manufactured to the highest quality standards and will protect your customers hands from harm while working. Leave your customized information with us and let us help you customize your brand work gloves! We provide customized cut resistant gloves production service, so you can be sure that you’re getting the best possible product for your needs.

Leave your contact information in the form below and let us help you customize your brand work gloves today!

PTB SAFETY, YOUR PROTECTION GUARDIAN